Nautical design

Nautical design for M.A.G. Boats means technology, quality, attention to detail.

M.A.G. Boats, in fact, does not only deal with the creation of inflatable boats made in Italy and tubes in Hypalon neoprene, but thanks to its extensive experience, offers a 360° nautical design service.

The technical office of M.A.G. Boats is composed of engineers, architects and designers who follow every aspect of the design of boats of different types, from four to twenty metres, ensuring maximum professionalism, the use of the latest applications and technologies and the attentive eye of those who have been working in the nautical field for over two decades.

The flexibility of the internal technical office is further completed by the possibility of following each preliminary phase to the realisation of the boat up to the prototype.

PROJECT

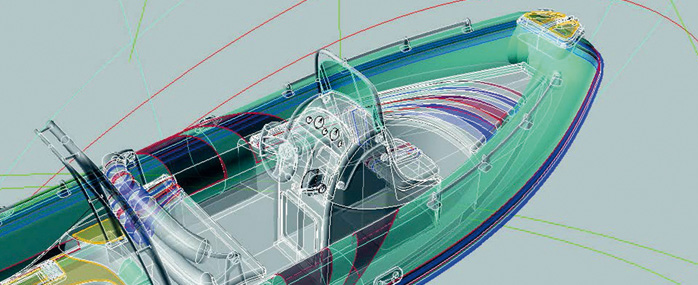

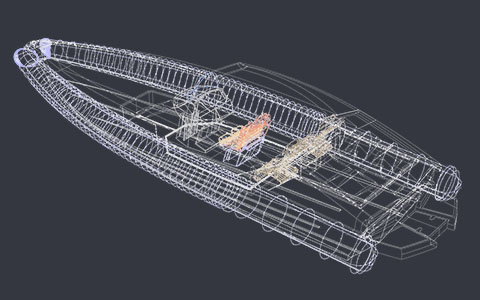

The first step of nautical design is the study and research phase, which seeks to analyse the operating context of the future vessel, the market in which it will be located, the competitors, technical challenges, production costs and the consequent expected revenues. After this first phase of the business plan, creativity takes space and we proceed to the moment of the design of the boat, studying its shapes, design, technical solutions. This leads to 3D modelling with precision to the millimetre, relying on the latest generation software that allows export in any format requested by the customer (IGES, DWG, DXF, STEP, SAT, STL or VDA).

CNC MILLING

The second step of the boat design process consists in the realisation of the models, carried out by means of 5-axis numerical control cutters that, reading the design file, give material form to what until now was only a 3D drawing.

Where required or preferable, one can decide to use CNC cutters that make it possible to directly create the pre-series moulds instead of the model.

PROTOTYPE

Once the printing of the individual elements is completed, we arrive at the last phase of the nautical design process, with the assembly of the first specimen — the prototype.

It is a very dedicated moment, during which the technicians lay out the systems according to the original design, install the accessories and make sure that all the details comply with the design provisions and are congruent with the actual operating situation that the boat will have to face.